welcome to Henan Pingyuan Mining Machinery Co., Ltd.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-30 Origin: Site

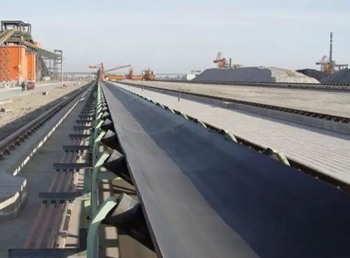

In today’s fast-paced industrial landscape, efficient material handling is fundamental to operational success. Whether it’s in manufacturing plants, construction sites, or large warehousing facilities, the choice of conveyor systems can significantly affect productivity, safety, and cost management. Among the most popular equipment for bulk and unit material movement are belt conveyors—specifically, fixed and portable belt conveyors.

Both fixed and portable belt conveyors serve the purpose of transporting materials from one point to another, but they differ considerably in design, application, flexibility, and cost. Selecting the right conveyor type tailored to your operation’s unique needs is crucial for optimizing workflow, reducing downtime, and improving labor efficiency.

Fixed belt conveyors are permanently installed systems designed to transport materials along a fixed path within a facility or site. These conveyors are built into the infrastructure, often anchored to the floor or structural supports, and are intended for continuous, long-term use.

Permanent Installation: Fixed conveyors require groundwork, including foundations or mounting supports, making them a semi-permanent part of a facility’s infrastructure.

Heavy-Duty Design: Built for high-capacity, long-distance, and continuous operation, fixed belt conveyors can handle heavy and abrasive materials.

Customizable Layouts: They can be configured in straight lines, curves, inclines, or multiple levels to fit complex workflows and maximize space utilization.

Integration Capability: Fixed systems are often integrated with other automated equipment such as robotic arms, sensors, and warehouse management systems (WMS), enabling advanced automation.

Durability and Stability: These conveyors are robust, made with heavy-duty frames and components designed to withstand rigorous industrial environments.

Fixed belt conveyors are prevalent in large-scale manufacturing, mining, quarrying, warehousing, and food processing industries where consistent, high-volume material transport is required.

Portable belt conveyors, also known as mobile or flexible conveyors, are designed with mobility and flexibility in mind. Equipped with wheels or casters, these conveyors can be easily moved and repositioned as needed, making them ideal for dynamic work environments.

Mobility: Portable conveyors can be transported to different locations within a facility or job site with minimal effort.

Lightweight and Compact: Their designs emphasize ease of transport and setup, often with foldable or modular frames.

Quick Installation: Portable conveyors can be quickly deployed or dismantled, reducing downtime and setup costs.

Versatility: Suitable for a wide variety of materials and adaptable to changing operational requirements.

Lower Initial Cost: Typically less expensive upfront compared to fixed conveyors, making them attractive for short-term or budget-conscious projects.

Portable belt conveyors are commonly used in construction sites for moving debris and materials, temporary warehouse setups, agricultural operations, and event logistics where the layout frequently changes.

When deciding between fixed and portable belt conveyors, it’s important to consider several crucial factors related to your operation’s needs.

Fixed Belt Conveyors: Require professional installation and are anchored in place. Once installed, they rarely move, making them suitable for stable, long-term production lines.

Portable Belt Conveyors: Designed for quick setup and movement. Ideal for environments where material flow paths change regularly or multiple locations need coverage.

Fixed: Typically engineered to handle heavier loads over longer distances continuously, making them perfect for large-scale, high-volume operations.

Portable: More suited for moderate loads and shorter distances. Not generally recommended for extremely heavy or abrasive materials over long runs.

Fixed: Higher initial investment due to installation complexity, foundation work, and customization. However, their durability and efficiency can lead to cost savings over time.

Portable: Lower upfront cost and installation expenses. Cost-effective for temporary needs or businesses with fluctuating operational demands.

Fixed: Less flexible once installed. Changing the layout requires significant work and expense.

Portable: Highly flexible and can be reconfigured or relocated with ease to meet evolving production requirements.

Fixed: Designed for long-term use, often requiring scheduled maintenance but generally offering longer service life.

Portable: Easier to maintain due to simpler construction but might experience more wear from frequent handling and relocation.

Fixed conveyors provide consistent, uninterrupted transport of materials, improving throughput and reducing bottlenecks in production lines.

Built with heavy-duty components, fixed belt conveyors withstand harsh operating conditions, including extreme temperatures, abrasive materials, and high-impact loads.

Fixed conveyors easily incorporate sensors, sorters, and control systems, enabling streamlined and automated material handling solutions.

With fixed conveyors, permanent safety installations such as guards, emergency stops, and controlled access can be systematically implemented.

Portable conveyors can be moved quickly to respond to shifting priorities, making them perfect for dynamic work sites.

Rapid deployment reduces the need for manual material handling, cutting labor costs and minimizing worker fatigue and injury risk.

Ideal for businesses with seasonal spikes, temporary projects, or multi-location needs, portable conveyors avoid costly permanent installations.

When not in use, portable conveyors can be stored away safely, freeing valuable floor space.

Fixed conveyors dominate manufacturing environments where repeatability and efficiency are critical. For example, automotive assembly lines rely heavily on fixed belt conveyors to transport components between workstations smoothly and predictably.

Construction sites benefit from portable conveyors due to the constantly changing work areas and project phases. Transporting aggregate, sand, and debris between zones is simplified by mobile conveyor solutions.

Both types have roles here: fixed conveyors handle bulk parcel sorting and long-distance internal logistics, while portable conveyors serve temporary loading/unloading stations or supplement peak demand workflows.

Portable conveyors often assist in seasonal harvest operations, while fixed systems support continuous processing in food production plants.

Consider the nature of your materials (weight, abrasiveness, moisture content) to select a conveyor built for those conditions.

Evaluate your facility layout, space availability, and environmental factors such as dust, humidity, and temperature.

Longer conveyor runs and higher throughput generally favor fixed conveyors, while short, flexible runs align with portable models.

Analyze the total cost of ownership—including purchase, installation, maintenance, and operational costs—against productivity gains.

Choosing between fixed belt conveyors and portable belt conveyors depends on a clear understanding of your operation’s unique material handling requirements, budget constraints, and future growth plans. Fixed belt conveyors are ideal for stable, high-volume, long-term applications, offering excellent durability and seamless integration with automated systems. On the other hand, portable belt conveyors provide unmatched flexibility and cost efficiency, making them perfect for dynamic, short-term, or multi-location operations. By carefully evaluating factors such as load capacity, mobility, installation ease, and overall cost, you can select the conveyor system that best supports your operational goals, leading to smoother workflows, improved safety, and optimized resource utilization.

If you are considering investing in belt conveyor technology or need expert advice tailored to your industry, Henan Pingyuan Mining Machinery Co., Ltd. is a trusted partner to explore. With extensive experience and a comprehensive product range, they offer customized solutions designed to meet your specific needs. Contact Henan Pingyuan Mining Machinery Co., Ltd. today to learn how their advanced conveyor systems can enhance your material handling processes and drive your business success.