Bucket Elevators: The Vertical Solution for Bulk Material Transport

Safely and efficiently transport bulk materials to new heights with our robust and reliable vertical conveyor systems.

Products Introduce

A bucket elevator is a mechanical conveying system designed to lift bulk materials vertically. It consists of a series of buckets attached to a continuous belt or chain, which moves from a lower intake point to an upper discharge point. This system is essential for industries that need to transport granular, powdery, or lumpy materials between different levels of a facility. Our bucket elevators are engineered for high-capacity, dependable operation, providing a powerful and space-saving solution for your material handling needs.

Product Center

Product Advantages

⦁ Maximized Space and Efficiency Instead of bulky, floor-intensive systems, our bucket elevators use a vertical, compact footprint. This design allows you to move materials with a minimal-sized casing, which is perfect for facilities where every square meter of floor space is valuable. This also makes them ideal for integrating into existing production lines without a major overhaul of your plant's layout.

⦁ Tangible Energy and Cost Savings Our drive system is built for peak efficiency, not just power. The motors are precisely matched to the elevator's load and speed requirements, preventing the energy waste that's common with oversized motors. Additionally, our system's low-friction design reduces drag, so less power is needed to lift materials. This translates into lower electricity bills and a smaller environmental footprint for your business.

⦁ Reduced Downtime and Maintenance Costs Our elevators are constructed from heavy-gauge steel and use wear-resistant belts and chains. We've also designed key components like bearings and rollers for easy, direct access, which drastically cuts down the time required for routine checks and replacements. This focus on durability and serviceability means you spend less time and money on maintenance and more time on production.

⦁ A Quieter, Safer Workspace Precision engineering isn't just a buzzword for us; it's a design principle. Our elevators feature balanced components and a finely tuned drive system that eliminates the rattling and loud vibrations common in lesser-quality machines. The result is a stable, smooth-running machine that operates with minimal noise, creating a quieter and safer environment for your workers.

Core Features & Technical Specifications

Vertical Lift Design

The system's core is a vertical lift structure, consisting of a lower boot section for material intake, a series of fully enclosed trunking sections that house the belt or chain, and an upper head section for material discharge. This design ensures maximum lift with a minimal footprint, providing a highly efficient solution for multi-level facilities.

Customizable Buckets & Belt/Chain

We offer a range of bucket types and materials to match your specific application. Buckets can be made from carbon steel, stainless steel, or durable plastic and are available in various styles for different material types. These buckets are mounted on a high-tensile rubber belt or a durable steel chain, chosen to provide the best performance for your load and operational speed.

Robust Drive & Tensioning Systems

The elevator is powered by a high-performance motor and gear reducer, ensuring smooth, consistent operation. A reliable take-up mechanism at the boot or head section allows for precise tensioning of the belt or chain, which is critical for preventing slippage and ensuring optimal performance and service life.

Contact Us

Application

FAQs

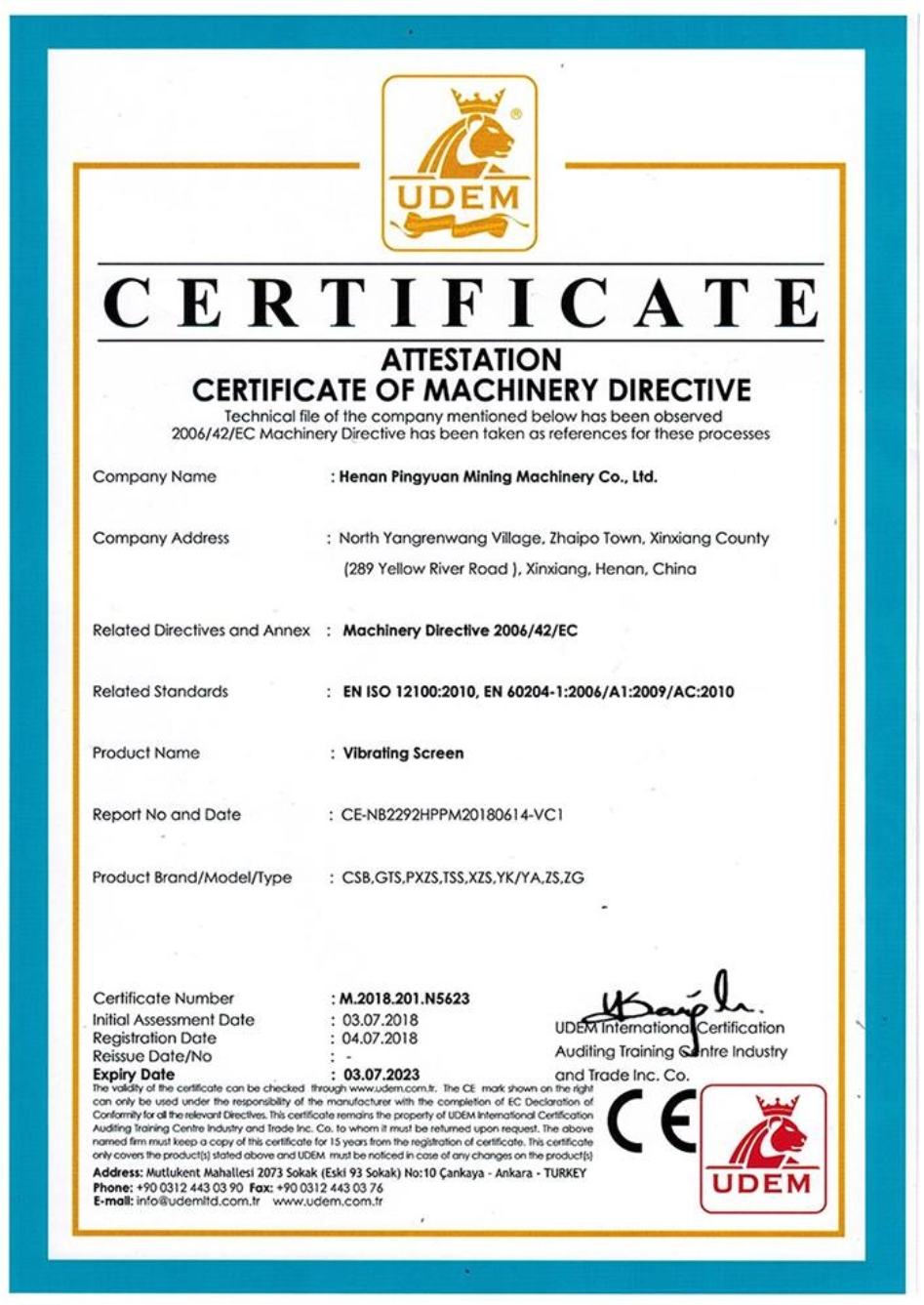

Our Certificate

Backed by rigorous quality standards and various certifications, we are dedicated to providing products you can trust.

Related Blogs

-

The belt conveyor, as the "main artery" for material transportation, it is prone to hardening and cracking of the conveyor belt and a decrease in friction between the drum and the belt during winter due to low temperatures. Therefore, special attention should be paid to implementing anti-freezing, a

The belt conveyor, as the "main artery" for material transportation, it is prone to hardening and cracking of the conveyor belt and a decrease in friction between the drum and the belt during winter due to low temperatures. Therefore, special attention should be paid to implementing anti-freezing, a -

A new FY-1536 tumbl screen destined for a quartz sand processing project in Guyana, has rolled off the production line at PK Machinery. The unit has cleared all quality checks and is now awaiting shipment to the client.This robust tumbl screen (also called swing screen) is engineered specifically foNews

A new FY-1536 tumbl screen destined for a quartz sand processing project in Guyana, has rolled off the production line at PK Machinery. The unit has cleared all quality checks and is now awaiting shipment to the client.This robust tumbl screen (also called swing screen) is engineered specifically foNews -

A trommel screen is a versatile and widely used piece of equipment for processing and separating solid materials. It consists of a rotating cylindrical drum with perforated walls, which allows materials to be sorted according to size. Trommel screens are known for their efficiency, reliability, and ability to handle large volumes of materials, making them indispensable in multiple industries worldwide. Their primary function is to separate, classify, and grade materials based on particle size, ensuring smooth downstream processing, reducing waste, and improving productivity.News

A trommel screen is a versatile and widely used piece of equipment for processing and separating solid materials. It consists of a rotating cylindrical drum with perforated walls, which allows materials to be sorted according to size. Trommel screens are known for their efficiency, reliability, and ability to handle large volumes of materials, making them indispensable in multiple industries worldwide. Their primary function is to separate, classify, and grade materials based on particle size, ensuring smooth downstream processing, reducing waste, and improving productivity.News -

Trommel screens are versatile machines designed to separate and classify materials efficiently. Their wide variety of types and configurations is driven by the diversity of materials handled, the processing capacity required, and the specific needs of different industries. Whether dealing with solid waste, mining ore, compost, or construction debris, selecting the appropriate trommel screen is essential to ensure smooth operations, minimize downtime, and improve overall processing efficiency. The correct type of trommel screen can help reduce operational costs, optimize material recovery, and extend equipment lifespan. Businesses across various sectors, from municipal waste management to large-scale mining operations, rely on trommel screens for their adaptability and reliability in handling both heavy-duty and delicate materials.News

Trommel screens are versatile machines designed to separate and classify materials efficiently. Their wide variety of types and configurations is driven by the diversity of materials handled, the processing capacity required, and the specific needs of different industries. Whether dealing with solid waste, mining ore, compost, or construction debris, selecting the appropriate trommel screen is essential to ensure smooth operations, minimize downtime, and improve overall processing efficiency. The correct type of trommel screen can help reduce operational costs, optimize material recovery, and extend equipment lifespan. Businesses across various sectors, from municipal waste management to large-scale mining operations, rely on trommel screens for their adaptability and reliability in handling both heavy-duty and delicate materials.News

Keep In Touch With Us

If you have any questions or requirements regarding bucket elevator, please feel free to contact our customer service team. Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+86-18236198171

E-mail:info@pkmachinery.com