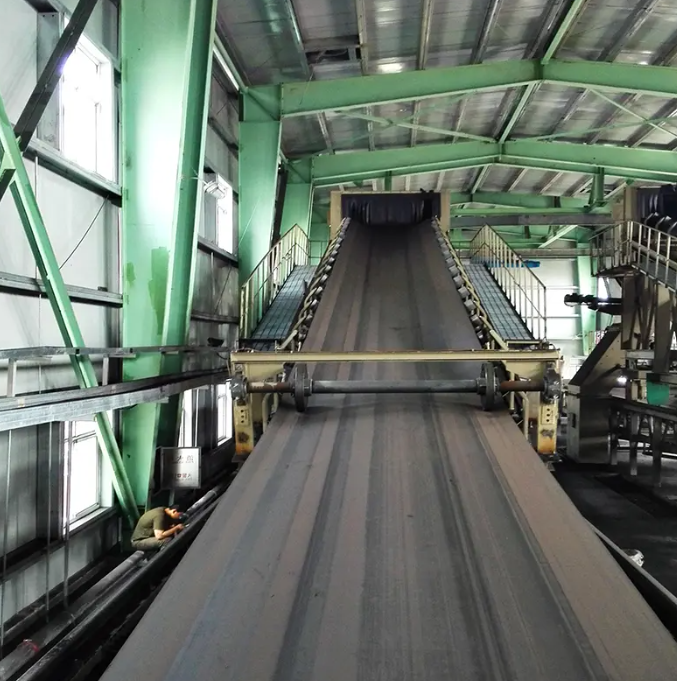

Belt Conveyors: The Backbone of Modern Material Handling

Streamline your operations with our reliable, high-capacity, and versatile belt conveyor solutions.

Products Introduce

A belt conveyor is an essential piece of equipment in the material handling industry, designed to transport goods, materials, or products from one point to another. It consists of a continuous loop of a durable belt that moves over a series of pulleys and rollers. Our belt conveyor systems are engineered for high-performance and durability, offering a flexible and efficient solution for a wide range of industries, from manufacturing and warehousing to mining and agriculture. We provide a variety of customizable belt conveyors to meet the specific demands of your operational flow.

Product Center

Product Advantages

⦁ High Efficiency & Throughput Our belt conveyors are capable of handling a vast volume of materials, ensuring a continuous and high-speed flow of goods. This leads to significantly improved productivity and operational efficiency compared to manual labor or other transport methods.

⦁ Versatility in Application Designed to adapt to various environments, our belt conveyors can handle a wide range of materials, including bulk goods (like sand and grain), packaged products, and individual items. They can be configured to move materials horizontally, on an incline, or even on a decline, making them suitable for complex layouts.

⦁ Low Maintenance & Long Service Life Built with robust components and a simple design, our systems require minimal maintenance. High-quality bearings, rollers, and motors ensure reliable, long-term operation, reducing downtime and lowering total cost of ownership.

⦁ Safety & Reliability Our conveyors are equipped with advanced safety features, including emergency stop switches, belt misalignment sensors, and overload protection. These features ensure a safe working environment and protect your investment by preventing damage and operational failures.

Technical Specifications

Belt Materials

Available in a range of materials including PVC, rubber, and polyurethane to suit different applications and material types.

Frame & Structure

Made from durable materials such as carbon steel, stainless steel, and aluminum, with options for modular or custom-built frames.

Drive System

Equipped with high-performance motors and gear reducers to ensure smooth and powerful operation, even under heavy loads.

Contact Us

Application

FAQs

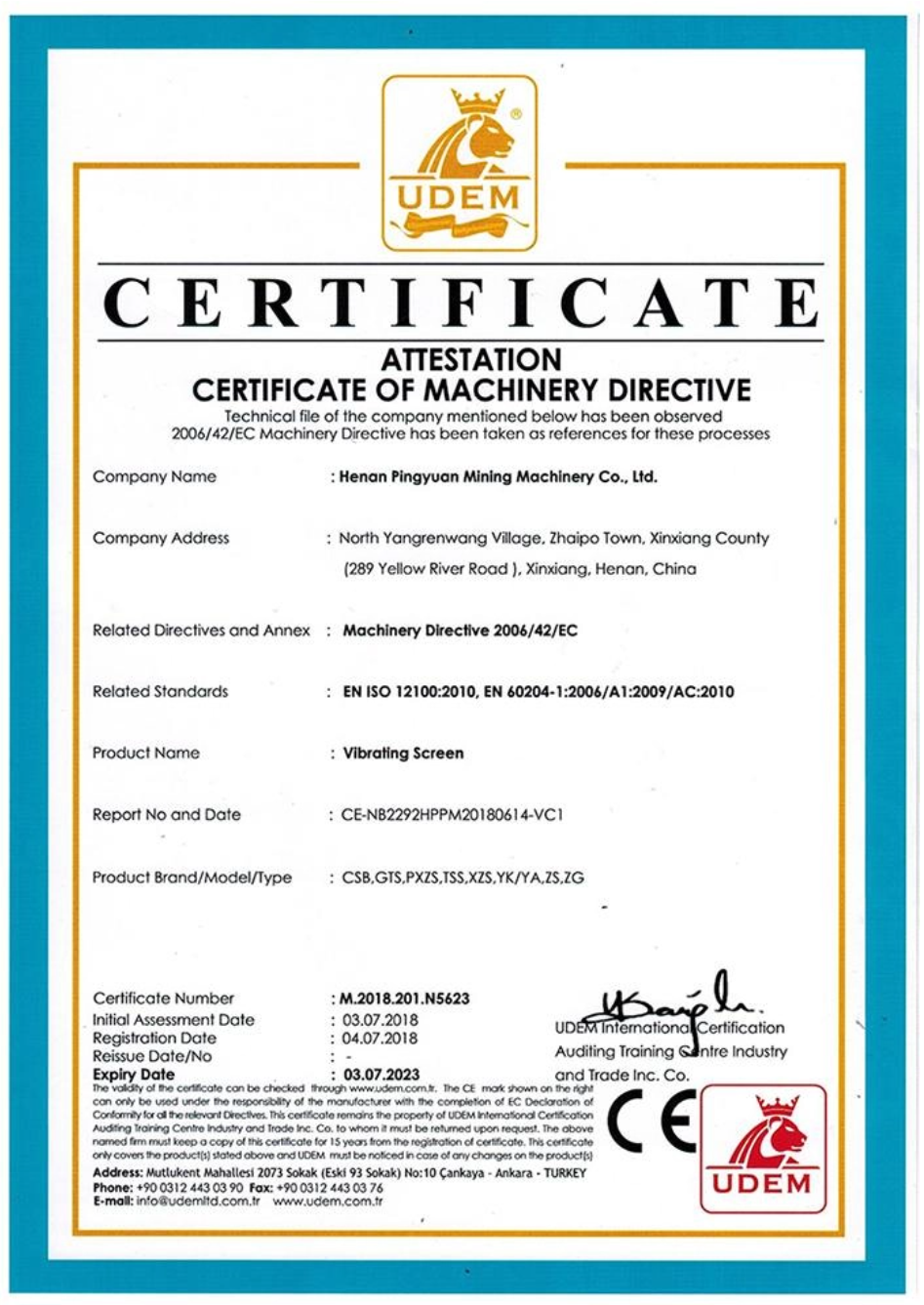

Our Certificate

Backed by rigorous quality standards and various certifications, we are dedicated to providing products you can trust.

Related Blogs

-

The belt conveyor, as the "main artery" for material transportation, it is prone to hardening and cracking of the conveyor belt and a decrease in friction between the drum and the belt during winter due to low temperatures. Therefore, special attention should be paid to implementing anti-freezing, a

The belt conveyor, as the "main artery" for material transportation, it is prone to hardening and cracking of the conveyor belt and a decrease in friction between the drum and the belt during winter due to low temperatures. Therefore, special attention should be paid to implementing anti-freezing, a -

A new FY-1536 tumbl screen destined for a quartz sand processing project in Guyana, has rolled off the production line at PK Machinery. The unit has cleared all quality checks and is now awaiting shipment to the client.This robust tumbl screen (also called swing screen) is engineered specifically foNews

A new FY-1536 tumbl screen destined for a quartz sand processing project in Guyana, has rolled off the production line at PK Machinery. The unit has cleared all quality checks and is now awaiting shipment to the client.This robust tumbl screen (also called swing screen) is engineered specifically foNews -

A trommel screen is a versatile and widely used piece of equipment for processing and separating solid materials. It consists of a rotating cylindrical drum with perforated walls, which allows materials to be sorted according to size. Trommel screens are known for their efficiency, reliability, and ability to handle large volumes of materials, making them indispensable in multiple industries worldwide. Their primary function is to separate, classify, and grade materials based on particle size, ensuring smooth downstream processing, reducing waste, and improving productivity.News

A trommel screen is a versatile and widely used piece of equipment for processing and separating solid materials. It consists of a rotating cylindrical drum with perforated walls, which allows materials to be sorted according to size. Trommel screens are known for their efficiency, reliability, and ability to handle large volumes of materials, making them indispensable in multiple industries worldwide. Their primary function is to separate, classify, and grade materials based on particle size, ensuring smooth downstream processing, reducing waste, and improving productivity.News -

Trommel screens are versatile machines designed to separate and classify materials efficiently. Their wide variety of types and configurations is driven by the diversity of materials handled, the processing capacity required, and the specific needs of different industries. Whether dealing with solid waste, mining ore, compost, or construction debris, selecting the appropriate trommel screen is essential to ensure smooth operations, minimize downtime, and improve overall processing efficiency. The correct type of trommel screen can help reduce operational costs, optimize material recovery, and extend equipment lifespan. Businesses across various sectors, from municipal waste management to large-scale mining operations, rely on trommel screens for their adaptability and reliability in handling both heavy-duty and delicate materials.News

Trommel screens are versatile machines designed to separate and classify materials efficiently. Their wide variety of types and configurations is driven by the diversity of materials handled, the processing capacity required, and the specific needs of different industries. Whether dealing with solid waste, mining ore, compost, or construction debris, selecting the appropriate trommel screen is essential to ensure smooth operations, minimize downtime, and improve overall processing efficiency. The correct type of trommel screen can help reduce operational costs, optimize material recovery, and extend equipment lifespan. Businesses across various sectors, from municipal waste management to large-scale mining operations, rely on trommel screens for their adaptability and reliability in handling both heavy-duty and delicate materials.News

Keep In Touch With Us

If you have any questions or requirements regarding belt conveyor, please feel free to contact our customer service team. Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+86-18236198171

E-mail:info@pkmachinery.com