welcome to Henan Pingyuan Mining Machinery Co., Ltd.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

KN

PK

8428330000

High Tensile Mining Reversible Shuttle Conveyor is a versatile material handling system designed for efficient bidirectional transportation of bulk goods (such as coal, grains, or minerals) within limited spaces.

Equipped with motorized wheels or tracks, it moves laterally along fixed rails to distribute materials evenly across multiple storage bins or processing lines. Key features include adjustable travel speed (typically 0.1–0.5 m/s), load capacities up to 2000 tons/hour, and programmable logic controller (PLC) automation for precise positioning.

Common in mining, agriculture, and logistics, its retractable design minimizes dead zones while optimizing storage space utilization. Advanced models integrate IoT sensors for real-time load monitoring and predictive maintenance.

1. The whole machine can move and reciprocate bidirectional unloading: The reversible distribution belt conveyor can move as a whole to realize reciprocating bidirectional unloading. This feature makes it very flexible in space utilization. The position and discharge direction can be adjusted as needed, effectively saving land utilization costs

2. Small space: Due to the design of the reversible distribution belt conveyor, the space occupied during work is relatively small, which is very beneficial for the limited space operation environment.

3. Stable transportation state: The conveyor shows stable performance during transportation, which is very important to ensure the safe transportation of materials

4. Wide range of use and low investment cost: The reversible distribution belt conveyor is suitable for a variety of scenarios.

5. Easy installation: Due to the compact structure, the installation process is relatively easy, which can save a lot of installation time and labor costs

● Reversible belt direction and there is no restrict to which end of the conveyor material can discharge from.

● It can discharge continuously in a long distance.

● The stationary material feed chute allows for processed material to be directed to one central location.

● Also can be controlled from a remote location to reduce labor cost greatly.

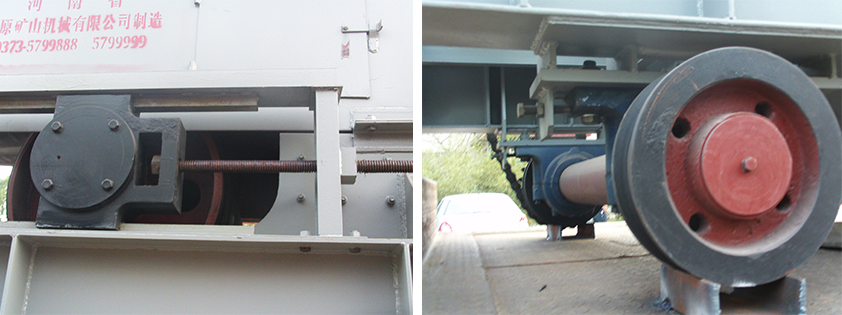

● Only heavy-duty, high quality drive components are used for our reversing shuttle conveyors.

● All of the moving components, from the trolley wheels to the drive motors, have been engineered to ensure continued functionality and reliability.

● Adopt high grade steel pulleys shafts for the pulley.

Photo

Belt width (mm) | Length (m) | Belt speed (m/s)/Track model(kg/m) | Walking speed (m/s) | Track distance (mm) | L×W×H(m) |

500 | 6~60 | ≤2.5/18 | 0.294 | 900 | 3265×1130×1080 |

650 | 1060 | 3265×1290×1080 | |||

800 | 1440 | 3265×1670×1210 | |||

1000 | 6~39 | 1640 | 3420×1870×1240 | ||

42~60 | 3690×1870×1240 | ||||

3920×1870×1240 | |||||

4000×1870×1240 | |||||

1200 | 6~30 | 1850 | 3400×2080×1400 | ||

33~60 | 3670×2080×1400 | ||||

3900×2080×1400 | |||||

4000×2080×1400 | |||||

1400 | 6~30 | 2050 | 3390×2280×1500 | ||

33~60 | 3660×2280×1500 | ||||

3890×2280×1500 | |||||

4000×2280×1500 |

Q1: What is a High Tensile Mining Reversible Shuttle Conveyor?

A: It is a heavy-duty belt conveyor system designed to move back and forth on a track, allowing material to be discharged at multiple points in either direction. It’s ideal for mining, bulk handling, and material stacking applications.

Q2: What makes it “reversible”?

A: The belt direction can be reversed, and the conveyor can travel forward and backward. This enables bidirectional unloading and the flexibility to discharge materials from either end of the conveyor.

Q3: What materials is it suitable for?

A: The shuttle conveyor is suitable for coal, ore, sand, gravel, cement, and other bulk materials, especially in high-load mining or processing environments.

Q4: What are the space advantages of this system?

A: It features a compact, low-footprint design, making it ideal for operations where space is limited. The shuttle motion also reduces the need for multiple conveyors or transfer points.

Q5: How does it reduce labor costs?

A: The system can be fully automated and controlled remotely, minimizing manual operation and improving safety and efficiency.