welcome to Henan Pingyuan Mining Machinery Co., Ltd.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-26 Origin: Site

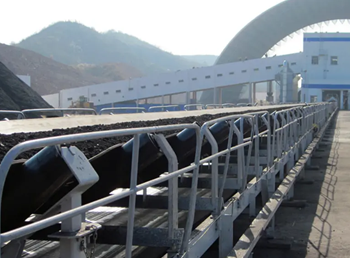

Transporting bulk materials efficiently over steep inclines is a common challenge across many industries, especially in mining, agriculture, construction, and chemical processing. When standard conveyor belts are used for steep or vertical transport, materials often tend to roll back, spill, or require multiple transfer points, which increases operational costs and maintenance downtime. To overcome these limitations, sidewall belt conveyors have emerged as a superior solution.

A sidewall belt conveyor is specially designed to move materials at steep angles—even up to 90 degrees—without slippage or rollback. With its unique structure featuring corrugated sidewalls and cleats, it ensures safe and continuous flow of materials in confined spaces or where horizontal space is limited.

One of the most significant issues with transporting materials on steep slopes is material rollback. When using conventional flat belt conveyors at steep angles, materials such as sand, coal dust, fertilizer, and grain may begin to slide back due to gravity, leading to spillage, safety risks, and inefficient operations.

Sidewall belt conveyors resolve this problem with two key design elements:

Corrugated Sidewalls: These flexible vertical walls are attached along both edges of the conveyor belt. They form a pocket-like structure that holds material securely on the belt surface, even when it travels vertically.

Cross Cleats (Flights): Mounted at regular intervals between the sidewalls, these cleats act as barriers that push the material upward as the belt moves. They prevent sliding and ensure a stable transport flow.

This design ensures that even free-flowing and fine materials can be conveyed reliably up steep inclines or even vertically. It minimizes the risk of material rollback, greatly reducing product loss and improving safety for workers in the vicinity.

Space constraints are a common challenge in modern industrial operations. Whether it’s an underground mining site, a compact warehouse, or a crowded port facility, floor space is often limited and expensive. This is where sidewall belt conveyors offer a major advantage: they allow for vertical or steep incline transport, reducing the overall conveyor footprint.

Space-Saving Layout: Unlike conventional conveyors that require long horizontal runs and gradual inclines, sidewall conveyors can transport materials vertically or in a zigzag fashion with minimal horizontal space. This is particularly beneficial in retrofitting old plants or optimizing layout in new facilities.

Reduced Conveyor Length: The vertical transport capability means shorter conveyor lengths are needed to achieve the same elevation change, which leads to cost savings in equipment and installation.

Flexibility in Plant Design: Sidewall conveyors can be installed in tight spaces, between levels, or along walls, giving engineers more flexibility when planning equipment layouts.

By optimizing space utilization, sidewall belt conveyors contribute to leaner facility designs and more efficient operations, particularly in industries where vertical lifting of materials is essential.

One of the standout features of sidewall belt conveyors is their ability to handle a wide range of bulk materials—from fine powders to large granules and irregular particles. Thanks to their secure containment design, they are suitable for both free-flowing and cohesive materials.

Sand and Gravel: Used in construction and mining, these abrasive materials are easily carried at steep angles with minimal spillage.

Grain and Agricultural Products: Wheat, corn, soybeans, and other agricultural commodities can be transported vertically from silos or storage bins with no damage.

Coal Dust and Fly Ash: In power plants and coal processing facilities, sidewall belts ensure clean and contained handling of dusty, fine materials.

Fertilizer and Chemicals: These sometimes corrosive or reactive materials require safe and contained transport—something that sidewall belts offer with their enclosed pockets.

Wood Chips and Biomass: In biomass plants or wood processing factories, sidewall conveyors help move light, fluffy materials efficiently.

The versatility of sidewall belt conveyors makes them ideal for facilities that need to handle multiple types of materials, whether dry, moist, abrasive, or delicate.

Traditional belt conveyor systems often require several transfer points when transporting materials across varying elevations. Every transfer point introduces a risk of:

Material spillage

Dust generation

Blockages and bottlenecks

Increased wear and tear

Higher maintenance requirements

By using sidewall belt conveyors, these issues can be significantly reduced. Because the system can handle both horizontal and vertical movement in one continuous run, the number of transfer points is minimized. This leads to:

Reduced Spillage: Fewer transitions mean less opportunity for materials to fall off the belt, improving site cleanliness and reducing waste.

Lower Maintenance: Each transfer point typically requires additional chutes, hoppers, and dust control measures. Reducing these components decreases maintenance costs and system complexity.

Improved Reliability: With fewer moving parts and transitions, the risk of system breakdowns is lower, ensuring smoother operations and less downtime.

Better Safety: Enclosed design and fewer handling points result in less exposure of materials to open air, reducing dust inhalation risks and improving worker safety.

In short, sidewall belt conveyors contribute to cleaner, safer, and more cost-effective bulk handling operations.

Beyond the major benefits discussed above, sidewall belt conveyors offer several additional advantages:

Modern sidewall conveyor systems are designed for high-capacity operations, making them suitable for heavy-duty industrial applications. The size of the belt, the height of cleats, and the spacing of sidewalls can all be customized based on:

Type and size of material

Required throughput

Installation environment

Inclination angle

This level of customization ensures optimal performance for each specific application.

With the use of wear-resistant rubber belts, reinforced cleats, and durable sidewalls, these conveyors are built to last. Properly maintained systems can operate for years with minimal downtime, even in harsh environments.

Sidewall conveyors can be easily integrated into existing material handling systems. Whether you’re replacing old equipment or expanding your operation, their compact footprint and vertical flexibility make them an excellent choice.

The versatility of sidewall belt conveyors has led to their adoption across a wide range of industries:

Mining: Transporting coal, ores, and tailings vertically to reduce haulage costs.

Agriculture: Lifting grain from underground bins to silo tops.

Cement and Construction: Moving sand, limestone, and aggregate in limited spaces.

Chemicals and Fertilizers: Safe handling of corrosive or fine powdered products.

Recycling and Waste: Vertical transport of shredded waste or recyclables in compact plants.

Food Processing: Conveying grain, sugar, or flour in hygienic environments.

Their ability to function efficiently in varied settings and for diverse materials makes them a vital component of modern bulk handling systems.

As industries strive for more efficient, space-saving, and cost-effective material handling solutions, sidewall belt conveyors have emerged as a top choice for steep and vertical transport. Their ability to prevent material rollback, reduce transfer points, and handle various bulk materials ensures reliable and clean operation in demanding environments.

If your facility is facing challenges with steep incline conveying, Henan Pingyuan Mining Machinery Co., Ltd. offers high-quality, customizable sidewall belt conveyor systems designed to meet your specific needs. With decades of industry experience and a commitment to innovation, they provide reliable solutions backed by expert support. Contact Henan Pingyuan Mining Machinery Co., Ltd. today to learn more or request a tailored solution for your operation.